Aircraft engine inspections are built around the same goal: confirm internal condition before small problems become expensive failures. What has changed is the environment maintenance teams operate in. Modern turbine engines run hotter, pack more complexity into tighter spaces, and face higher expectations for documentation. Remote visual inspection, often called RVI, has become a primary way to meet those demands without removing the engine from the wing. Companies like USA Borescopes help maintenance teams keep inspections consistent by supplying borescopes and videoscopes built for aviation environments, along with accessories that support reliable documentation.

Why Aircraft Engine Inspections Have Changed

Engines have evolved quickly in the last decade. Higher efficiency targets push components closer to their design limits, especially in the hot section where thermal stress, oxidation, and coating wear can develop over time. Operators also need aircraft available more often, which reduces the appetite for unnecessary disassembly. Any inspection method that keeps the engine installed and shortens turnaround time has clear operational value.

Maintenance programs are also more evidence driven. A written note without visual proof is less useful when a finding is borderline or when multiple stakeholders need to align on the next step. RVI fits this reality because it produces images and video that can be attached to a maintenance record and reviewed by engineering, quality, or the engine manufacturer.

RVI in 2026: From Useful Option to Standard Practice

In 2026, RVI is not just for major events. It is routinely used for scheduled checks, troubleshooting, and confirmation after repairs. The reason is simple: visual access is often enough to answer the key maintenance question, is the component serviceable right now and is it trending in the right direction.

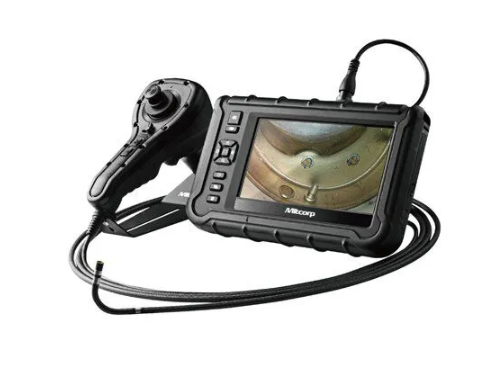

Modern borescopes and videoscopes support on wing checks of compressor blades, combustor liners, turbine nozzles, turbine blades, and stator vanes. They also help verify suspected issues such as foreign object damage, hot spot distress, or abnormal deposits. When findings are minor, the inspection can support a monitor decision rather than an immediate removal. When findings are serious, the inspection provides clear evidence that supports timely corrective action.

How Remote Visual Inspection Technology Has Evolved

RVI has advanced in three areas that matter most in real maintenance work: image quality, access control, and durability. Together, these improvements reduce uncertainty and make inspection results more repeatable.

Better Imaging, Better Decisions

High resolution sensors and improved optics make it easier to separate true defects from staining, reflections, or manufacturing marks. Adjustable lighting helps control glare on polished turbine surfaces and improves contrast on textured areas. Many systems also support digital zoom, image enhancement, and still capture during video. The practical impact is fewer missed indications and fewer false calls that trigger unnecessary work.

Measurement features are another important upgrade. When a technician can estimate defect length or width using on-screen tools, the resulting report is more consistent. That supports faster engineering decisions, especially when the team needs to compare a current image to a prior inspection.

Access and Tip Control in Complex Engines

Access ports may be designed for inspection, but the internal path is rarely simple. Articulation has become smoother and more precise, allowing technicians to inspect blade edges, platforms, and transition zones that are easy to miss with a fixed view. Probe diameter options help teams match the tool to the port size and the routing complexity.

Many maintenance organizations keep more than one configuration so they can handle both straight runs and tight turns. For teams evaluating options, the USA Borescopes product range can be a useful reference point for comparing probe sizes, articulation styles, and imaging features.

Durability Built for Field Conditions

Engine interiors are harsh. Residue, heat exposure, and sharp edges can damage an insertion tube or camera head. Aviation grade systems focus on reinforced construction, abrasion resistance, and reliable connectors that tolerate frequent setup and transport. Durability is not only about avoiding downtime for the tool. It also protects inspection quality, since a damaged probe can introduce image artifacts or reduce articulation control.

What Inspectors Look for in Modern Aircraft Engines

Even with better tools, the inspection target remains the same: find early signs of damage and confirm whether the condition is stable. Common focus areas include compressor damage from ingestion, combustor distress such as liner cracking or coating loss, and turbine issues such as thermal fatigue cracking, oxidation, erosion, tip rub, and signs of overheating.

Context matters. A small nick on a compressor blade may be acceptable depending on location and depth. A small crack in a hot-section component can be far more serious. RVI supports this judgment by enabling close inspection from multiple angles, with lighting changes that reveal surface texture.

Consistency also matters. Many teams follow a structured scan pattern, stage by stage, and capture images with clear orientation and labeling so results can be compared at the next interval.

A Practical RVI Workflow for 2026 Maintenance Teams

A strong workflow makes RVI more effective than simply owning a good scope. Preparation starts with the maintenance manual requirements and access planning. The technician selects probe length and diameter, checks articulation response, confirms image capture, and ensures the inspection path is clean enough to avoid contamination.

During navigation, controlled insertion and careful tip movement protect the probe and reduce the chance of missing a defect due to motion blur or poor angle. Technicians often pause to stabilize the view before capturing images, especially in the hot section, where reflections can mask fine crack lines.

Documentation is where modern RVI pays off. A good record includes the best still image, a short video sweep when helpful, and notes on location, stage, and suspected severity. Many teams also use internal image libraries to standardize calls and speed training for newer inspectors.

What Comes Next for RVI

The next wave of RVI progress is likely to be centered on data handling. Better integration with digital maintenance records can improve traceability and reduce manual steps. It can also support faster audits and cleaner handoffs between shifts and facilities. Assisted analysis tools may also become more common, helping technicians compare current images to prior baselines and highlight meaningful changes. Even as these features mature, the foundation will remain clear visuals, dependable control, and consistent documentation.

The Role of Trusted Inspection Equipment

Remote visual inspection has become a cornerstone of aircraft engine maintenance in 2026 because it supports faster decisions with less disruption. Better imaging, smoother articulation, and stronger durability have turned RVI into a reliable way to detect issues early, document findings clearly, and reduce unnecessary disassembly.

Choosing inspection equipment isn’t just about specs—it’s about whether the tool holds up during real maintenance work. USA Borescopes supports aviation teams with inspection systems built for shop and line environments, helping teams match equipment to actual inspection demands. Contact USA Borescopes to get guidance aligned with your maintenance needs.

About the Author

The author is an aviation inspection specialist with years of experience supporting engine maintenance and remote visual inspection programs. Their focus includes defect recognition, inspection techniques, and documentation standards that improve repeatability. They provide guidance to help maintenance teams reduce errors, speed decision-making, and strengthen compliance across routine inspections.